Discover the features of the autonomous mobile robot MiR.

Fully autonomous navigation

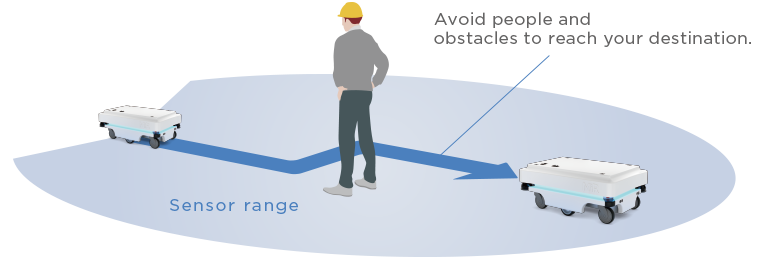

Automatically maneuvers around people and obstacles

Collaborative and autonomous

Safely maneuvers around people and obstacles in any dynamic environment.

Increased productivity

Can work round the clock, and chooses the fastest route to its destination while working.

Supporting changing business needs

Can easily adapt to changes in production items and facility layouts.

● Autonomous driving image

-

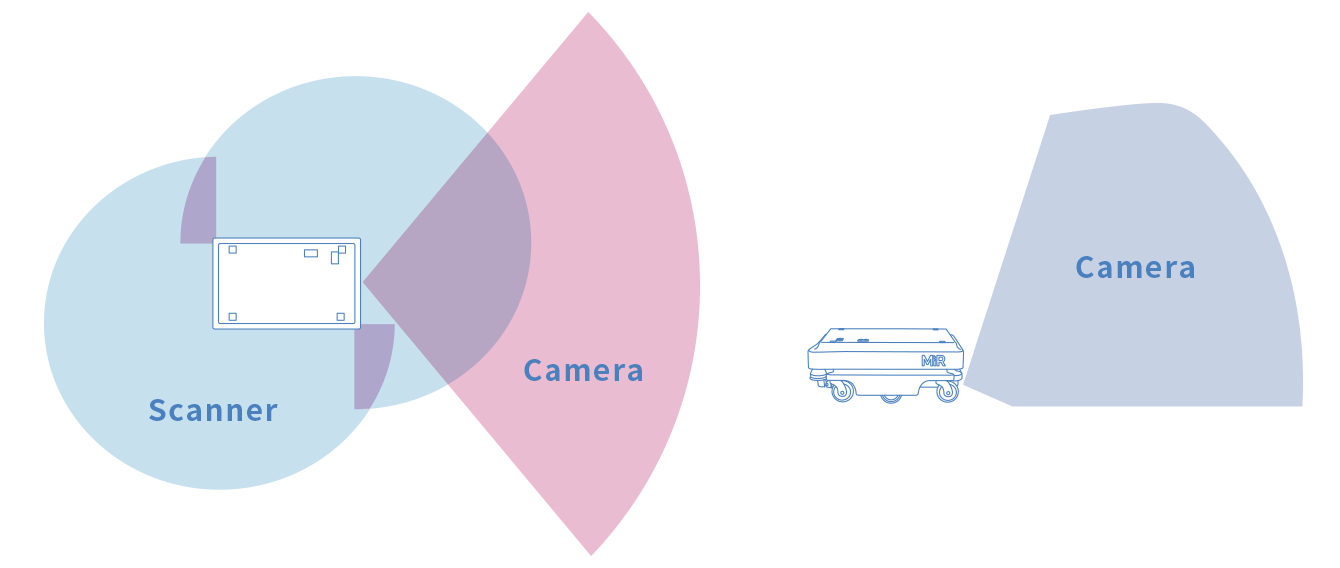

The world's first AI-equipped mobile robots

take robot navigation to a whole new level.Artificial intelligence (AI) capabilities built into the software and a camera that acts as an extended set of robot sensors enables optimized route planning and driving behavior in the MiR. The MiR AI camera allows the robot to detect and recognize various moving obstacles and react accordingly.

For example, when a person is detected, the robot will continue to drive normally, but when an AGV is detected, it will stop so that the AGV can pass. The robot can also anticipate and reroute blocked or high-traffic areas, instead of entering a blocked area and then rerouting.

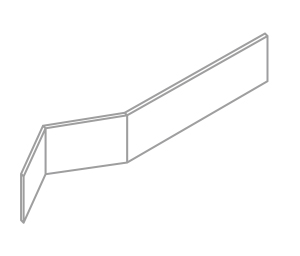

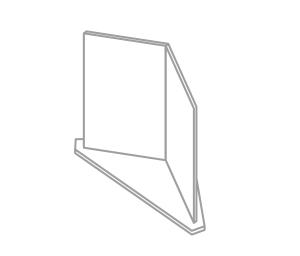

● Scanner and camera recognition range

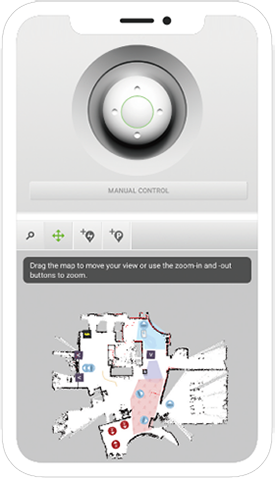

User-friendly operability

Easy programming with an easy-to-use GUI interface

User-friendly operability

A simple web-based interface that requires no programming experience makes it easy to handle.

Easy system setup

Setup can be done in as fast as a day. It can be deployed from the day after it arrives.

-

● Application operation screen(Example of smartphone)

* It can be operated on a PC, tablet, or smartphone equipped with a browser function.

-

● Deployment flow

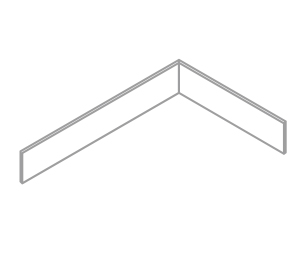

Position accuracy is further improved by installing markers

Use markers when you need to improve the robots’ position accuracy. Unlike common guides for AGVs such as magnetic tape, simply placing a marker helps the MiR stop with better accuracy. This means nothing is consumed and there is no need to regularly replace them. To change the stop position, just move the marker itself and register the point. Also, the relative position from the marker can be set as the stop position, which makes for extremely flexible use.

-

Marker types

Markers are boards that are installed to improve stop accuracy, and available in the following four types.

L marker

VL marker

V marker

Bar marker

High flexibility

Can be used for various tasks by changing top modules

From carrying small parts to transporting large products, the MiR can be customized to suit individual needs by mounting different top modules. It can automate the simple task of transporting things from A to B in a simple, efficient and cost-effective way.

Shelf Shelf

This top module is suitable for transporting many items at once, such as packaging products, supply parts, and manufacturing tools. It safely approaches to right next to the worker. It is the most basic type of top module and easy to install.

Conveyor

This is suitable for operations that connect conveyor lines, such as loading workpieces into the conveyor and receiving workpieces from the conveyor. It is ideal for controlling product flow in large factories and floors.

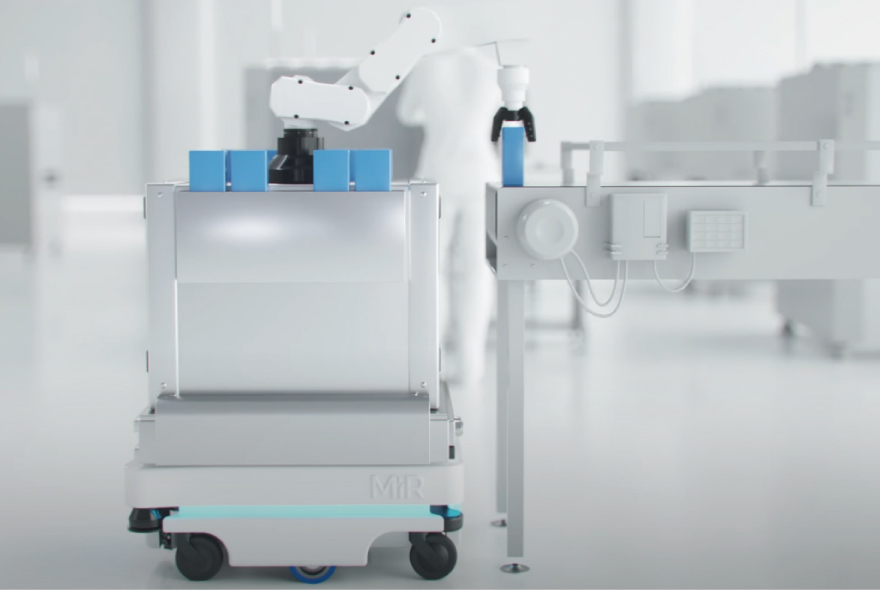

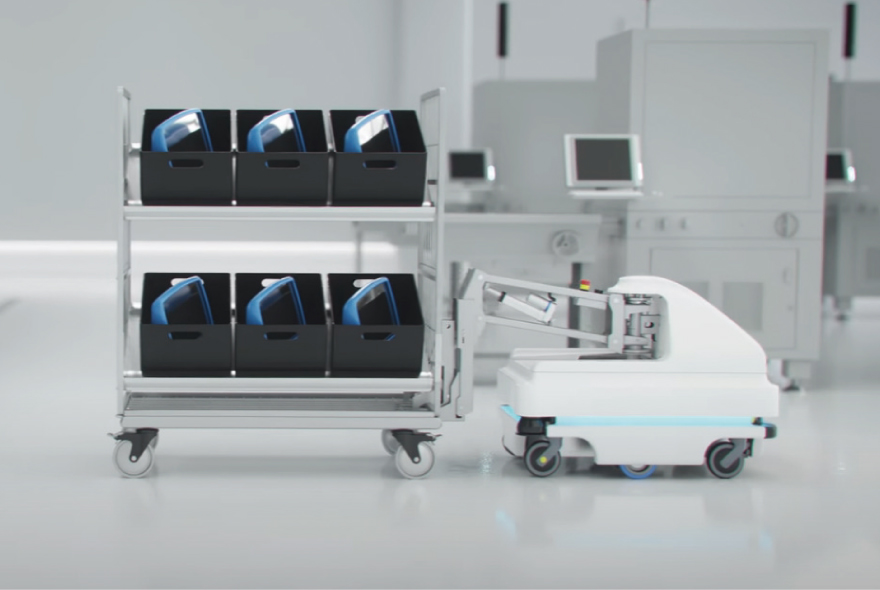

Robot Arm Robot Arm

Combining collaborative robots as a top module further expands the possibilities of the MiR. This is suitable for automation needs of work involving picking things from warehouse. It can collaborate with various robots such as UR and JAKA.

Hook

This is a genuine MiR top module that can fully autonomously pick up and tow various carts. It is suitable when it is necessary to move a cart loaded with workpieces in a manufacturing facility or warehouse. Even if there are carts of different sizes, they are identified by a QR code and safely towed to a predetermined location.

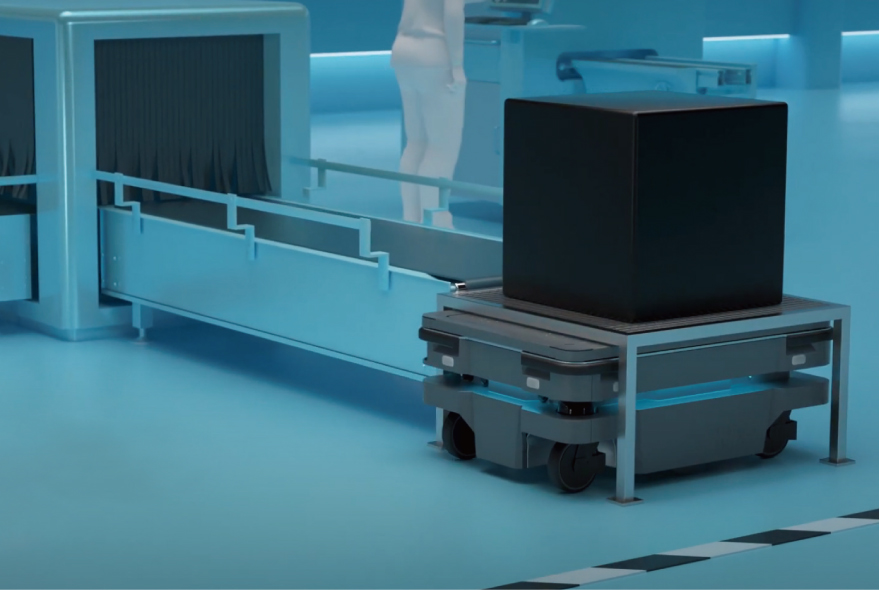

Lift Lift

This top module is ideal for transporting pallets and the like. By detecting obstacles with various sensors and avoiding them, the robot can safely move objects both on the way and when loading and unloading. It is mainly used in logistics warehouses and distribution areas in factories where heavy goods come and go.

Cart Cart

By going under a cart and docking, this module transports load along with the cart. It is the most flexible top module that can be used for any purpose because various things such as shelves, devices, pallets, and more can be freely placed on the cart.