Solutionmachine tending solution

Robotiq TOP / Solutions / Machine Tending Solutions

Robotiq Machine Tending Solution utilizes the features of Universal Robots to

It is a highly operable system solution for system startup and daily work.

In addition to the safety consulting capabilities of IDEC Factory Solutions,

We provide safe and secure automation systems.

Placement of workpieces on machine tools such as lathes, machining centers, multitasking machines, grinders, etc.

Universal robots automate repetitive tasks such as picking.

By using collaborative robots, there is no need to make major changes to existing installation layouts.

It is a highly productive system that can realize collaborative work such as periodic replacement of finished products and materials by humans without stopping the system.

It is possible to build an automated system.

Main features

Always-on peace of mind

Increase machine uptime and reduce downtime with solutions that work reliably.

Complex automation made simple

In general, automation of loading and unloading work to/from a CNC processing machine is complicated.However, Robotiq's machine tending solution is configured for easy setup from start to finish, so you can get started right away.

Fits on any processing machine

There is no need to modify the processing machine.Since the external module manages communication with the machine interface, it can be applied to processing machines of any manufacturer.It can significantly reduce the time required for implementation.

Fast payback

Robotiq machine tending co-pilot software saves time on machine loading and program switching.Realize automation of high-mix low-volume production.This shortens the period of return on investment.

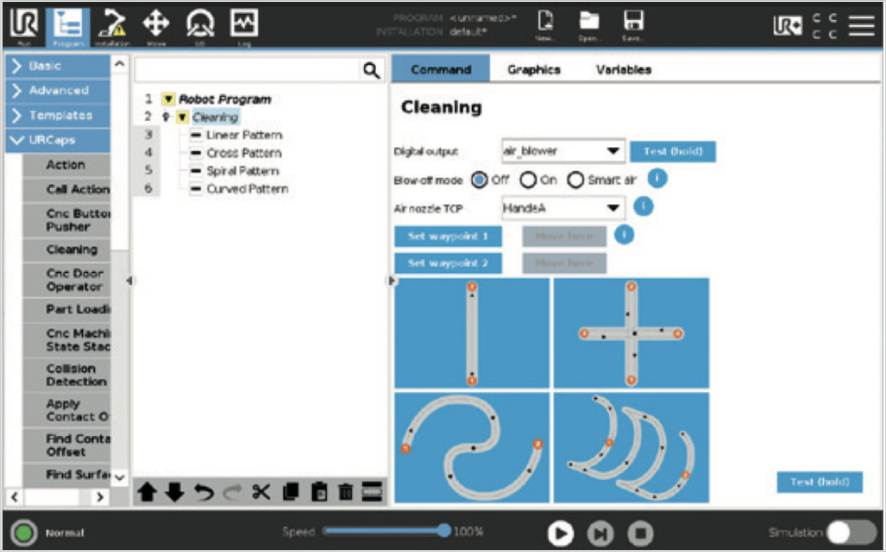

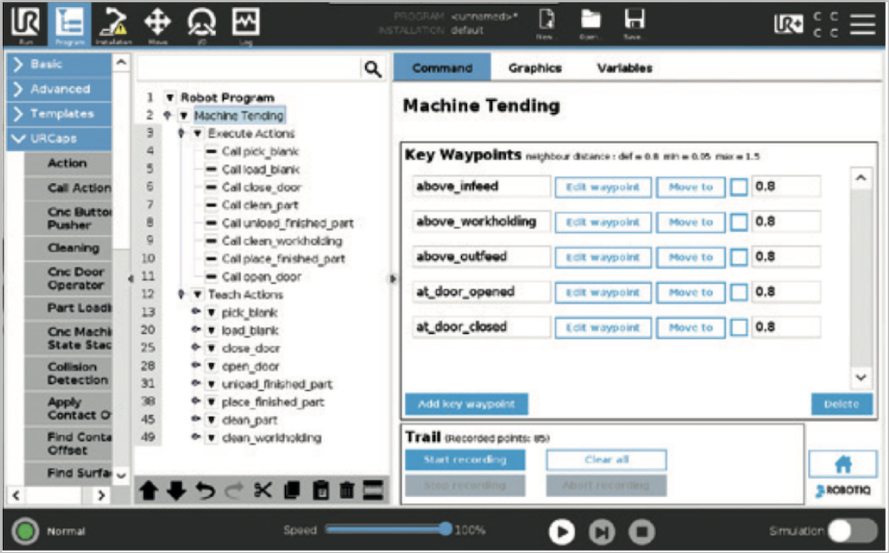

Program screen

Easy application setup in 3 steps

Simply set key reference points and adjust from the action menu to complete programming.Create programs 75% faster than before.

- 1

Set important reference points

Once set, they become the reference point for operations.

-

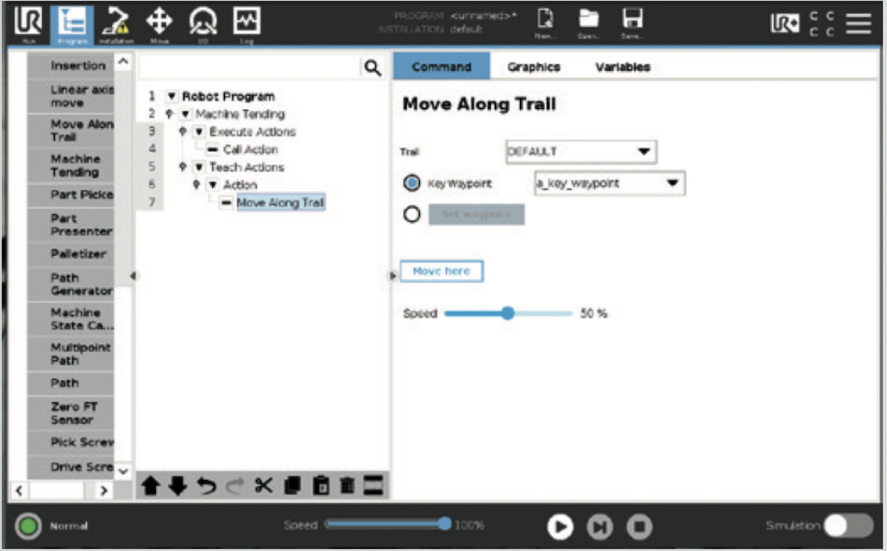

- 2

Increase precision of movement

Use the action menu to tailor it to your needs.

- 3

Create a smart move

Machine tending co-pilot software creates optimal movements between key reference points,

Find the best movement through the part transfer zone and automatically avoid collisions in the workcell.

Main components

●Single gripper kit

Main components

・Machine Tending Copilot Software

・Robotiq Machine Tending Controller

・Pneumatic control panel

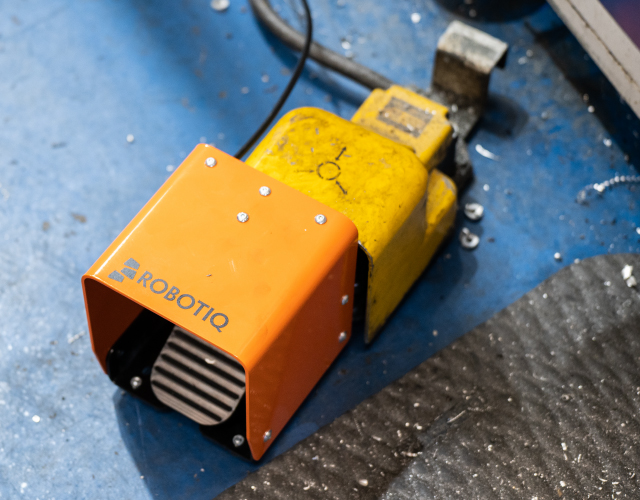

・Button activator

・Air nozzle kitGripper

・Hand-E gripper

・Machine Tending Fingertip Start Kitmachine interface

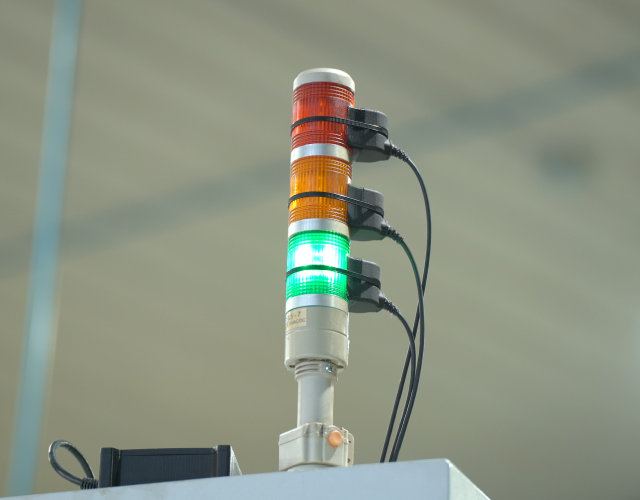

・Stack light detector

・Foot switch activatorOptions

・Wrist camera

・Robot stand-Dual gripper kit

Main components

・Machine Tending Copilot Software

・Robotiq Machine Tending Controller

・Pneumatic control panel

・Button activator

・Air nozzle kitGripper

・Hand-E gripper x 2

・Machine Tending Fingertip Start Kit x 2

・Dual bracket

・New compact dual bracket for Hand-Emachine interface

・Stack light detector

・Foot switch activatorOptions

・Wrist camera

・Robot stand

Spec.

-

Hand-e gripper Weight capacity (parallel gripping) 4.7kg Body weight 1kg IP rating 67 -

Robotiq Machine Tending Controller Nominal voltage DC24V/100mA pneumatic control panel energy source Air compressor (external air supply) Required supply pressure Minimum 600kpa, Maximum 800kpa Minimum required air flow 400 L/min (at 600kpa) Nominal voltage DC24V/33mA Number of box patterns Up to 2 types *Please contact us for detailed specifications and other components.

Movie

Refusal

This solution is for Universal Robots only.Not applicable to robots other than Universal Robots.Also, the Universal Robot itself is not included with this solution.

At IDEC Factory Solutions, we accept orders for a complete set including the Universal Robot itself.You can also use the Universal Robots you already have.

Please feel free to contact us for more information.