Robot SystemProductivity improvement

Solution for Automating Parts Transport for Multiple Processes

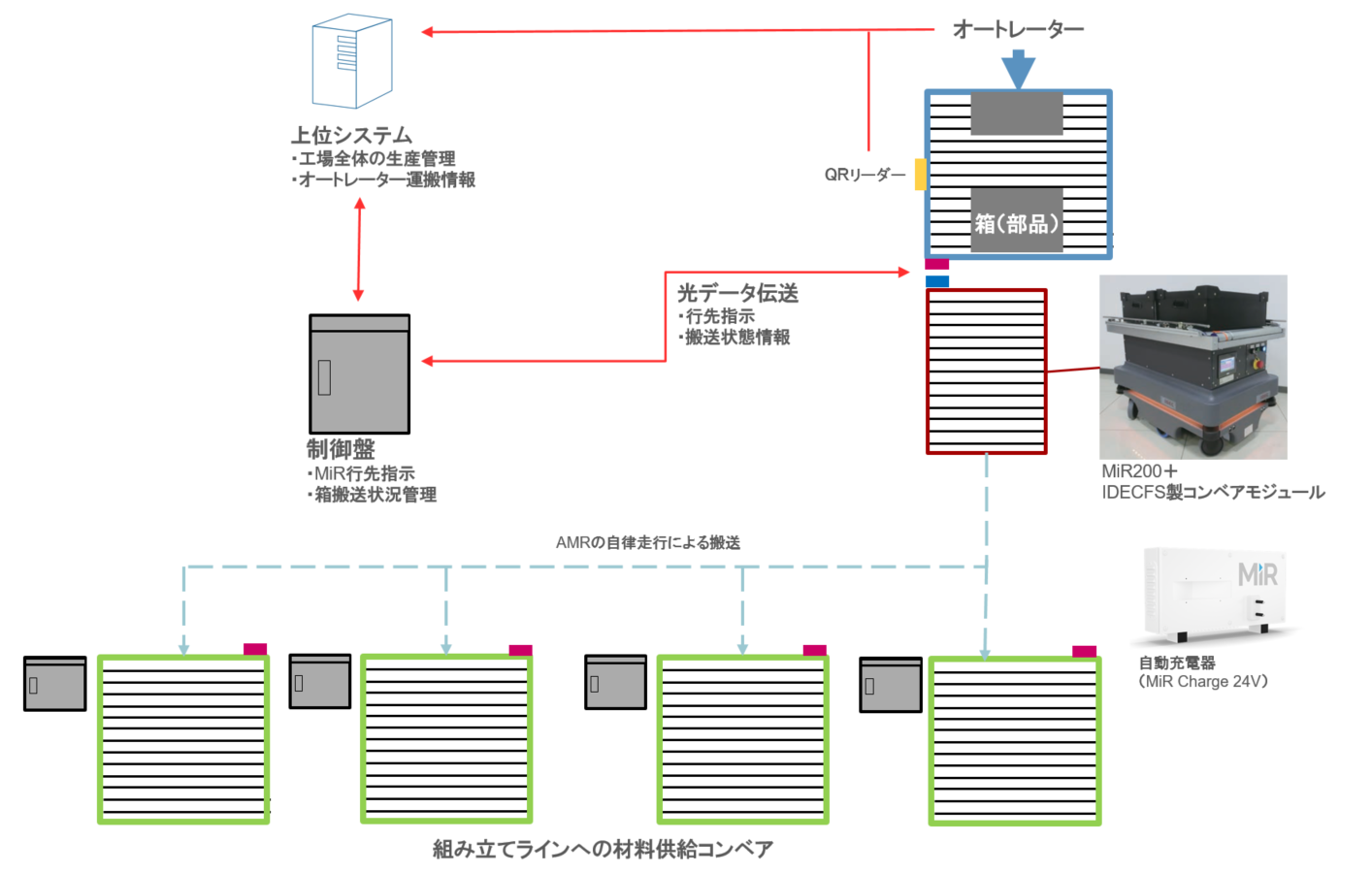

We constructed a system that can identify types of parts and automate the transport of them to multiple assembly areas via AMRs (autonomous mobile robots).

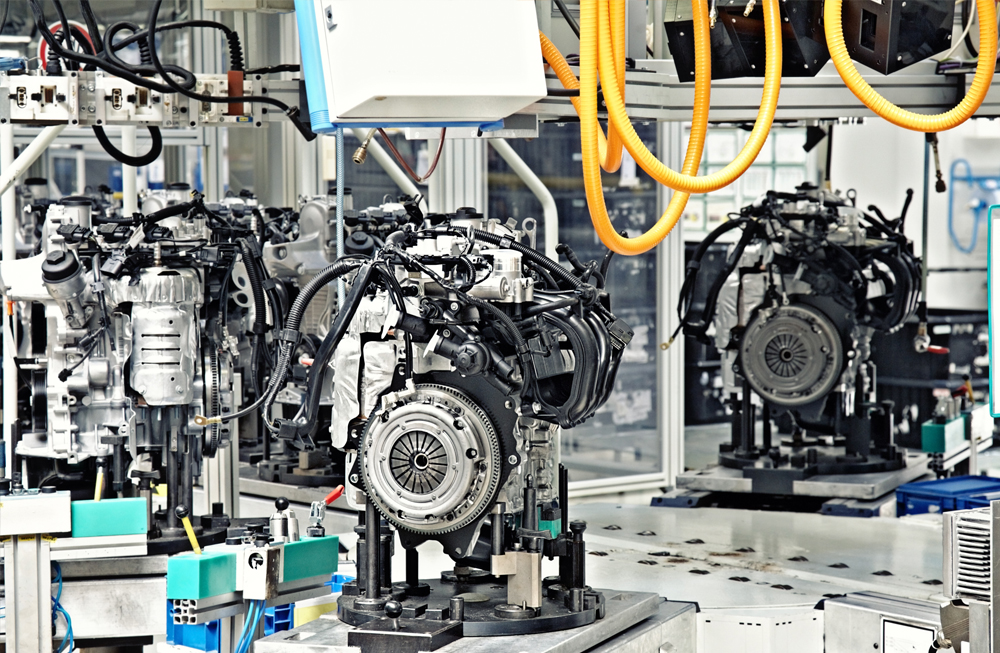

- Industry

- Manufacturing industry

- Solutions

- Productivity improvement

- System

- Robot System

Outline of the Case

Customer

Introduction Background

Medical equipment manufacturer Company E had already introduced an autolator that connected two floors as part of a factory-wide automation project.

As their next step, they were considering automatically receiving the cargo coming out of the autolator using AGV (AMR) and transporting it to the assembly area.

Since there are a dozen or so types of parts, it was essential to determine each one’s type and construct a system that could automatically direct the AGV (AMR) to the corresponding destination.

Furthermore, they wanted to be able to easily change the layout themselves and wanted the AGV to be able to avoid potential obstacles.

Introduced Solutions

-

We designed, manufactured, and introduced a conveyor-type top module on the autonomous running transport robot MiR200 which fulfilled the user's requests, such as the standards of the autolator and conveyor.

-

We constructed an AGV (AMR) system that automatically transports parts identified by QR code to multiple destinations in cooperation with the customer's host system.

Introduction Results

- ● Automated parts transport between conveyors from the autolator to the assembly area

Achieved - ● Contributed to the efficiency of the entire factory by linking with the host system

Products and Services Used

MiR200

IDECFS Conveyor Top Module

IDECFS Control Panel