Quality improvementSociety & InfrastructureAgriculture and livestock / Food product production

Solution for Greenhouse Agriculture Control (House and Irrigation Control)

Automating the control of ventilation windows in greenhouses for factors such as temperature and rainy weather

Irrigation levels have also been fine-tuned based on time settings, water levels in the soil, etc.

- Industry

- Agriculture:

- Solutions

- Quality improvement

- System

- Society & Infrastructure

Outline of the Case

Introduction Background

- ・ Agricultural cultivation in greenhouses was done through human intuition and experience and depended on each person's know-how, which is difficult to share and has hindered new workers.

- ・ Temperatures could not be controlled minutely according to seasons or weather conditions, and the environment could not be kept constant unless people constantly controlled it.

- ・ It is not possible to grasp a situation based on data such as temperature or humidity, or to store data on irrigation levels, etc., making it impossible to understand the optimal data and other factors needed in crop growth management.

- ・In order to construct a mechanism for automatic control and data collection, it was necessary to develop a separate dedicated microcomputer circuit board, but development and program updates could not be done easily. It was hard to maintain.

- ・ Watering amounts tended to depend on each person's experience and intuition, and it was not possible to minutely control irrigation levels in line with cultivation situations.

- ・ Irrigation according to actual situations such as water levels in the soil was impossible.

Introduced Solutions

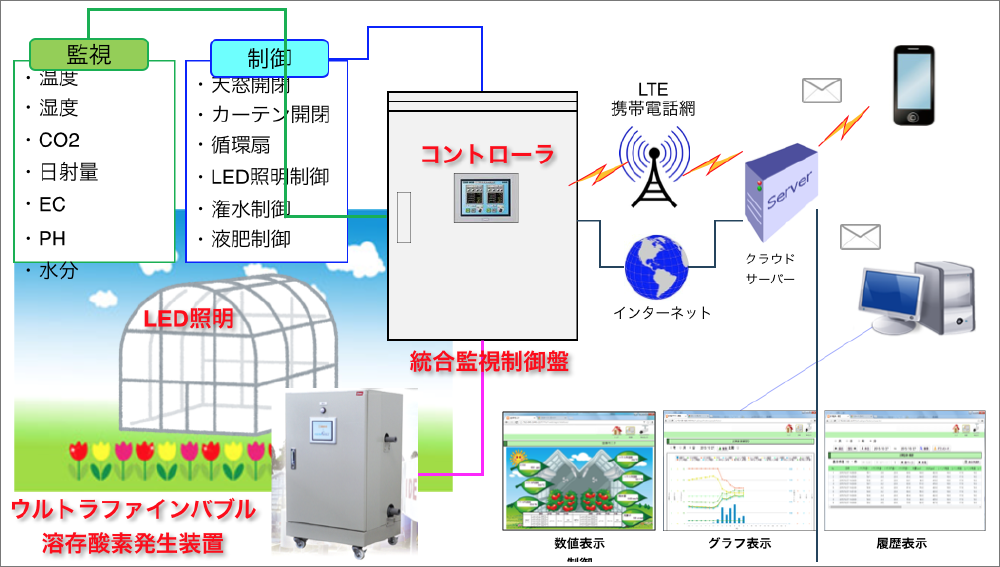

- Ventilation windows 2CH, curtains XNUMXCH, air circulation fans, COXNUMX generators, and heater or mist generator controls were introduced.

- Automatic controls were introduced that monitor temperature, CO2 concentration, humidity, and solar radiation levels with sensors and keep the environment constant by setting threshold values.

- Rain sensors detect rainy weather and automatically open and close the ventilation windows.

- Each sensor’s information is regularly uploaded to a cloud server via a mobile connection,

allowing workers to understand the year-round greenhouse environment. - Irrigation is done based on time controls, soil moisture sensors, etc.

- By combining the main panel with extension panels (16 units at most), it is possible to control irrigation for up to XNUMX systems at a relatively low cost.

- By connecting flow meters, actual irrigation levels can be controlled and their history can be managed and made into visuals.

Introduction Results

- ● Ventilation window control, curtain control, irrigation control, etc. can be done automatically based on information from each sensor, such as temperature and solar radiation.

Making regular rounds has now become unnecessary, which has helped work toward downsizing and labor reduction. - ● Automating the process of closing the ventilation windows in rainy weather with rain sensors

has made it possible to prevent quality loss. - ● Workers can grasp the cultivation situation through visualization, which is done by managing data from cultivation techniques based on intuition and experience.

Also, accumulating data has made it possible to understand the best conditions for each crop. - ● Workers can see the situation in the greenhouse via the cloud from mobile phones or other devices.

Remote monitoring and operations have become possible regardless of time or place, such as at night or when out and about.

Products and Services Used

● H2 type agricultural control panel

FT1A touch controller, FT1APLC, DC power supply, CP, terminal block, relay, and other items (made by IDEC), temperature / humidity / CO2 sensors, solar radiation sensor (made by other companies)

● K-type agricultural control main panel and extension panels

HG1G touch panel, FT1APLC, DC power supply, CP, terminal block, etc. (made by IDEC), solar radiation sensor, EC, PH sensor, soil moisture sensor (made by other companies)