Solutionscrew tightening solution

Robotiq TOP / Solutions / Screw tightening solutions

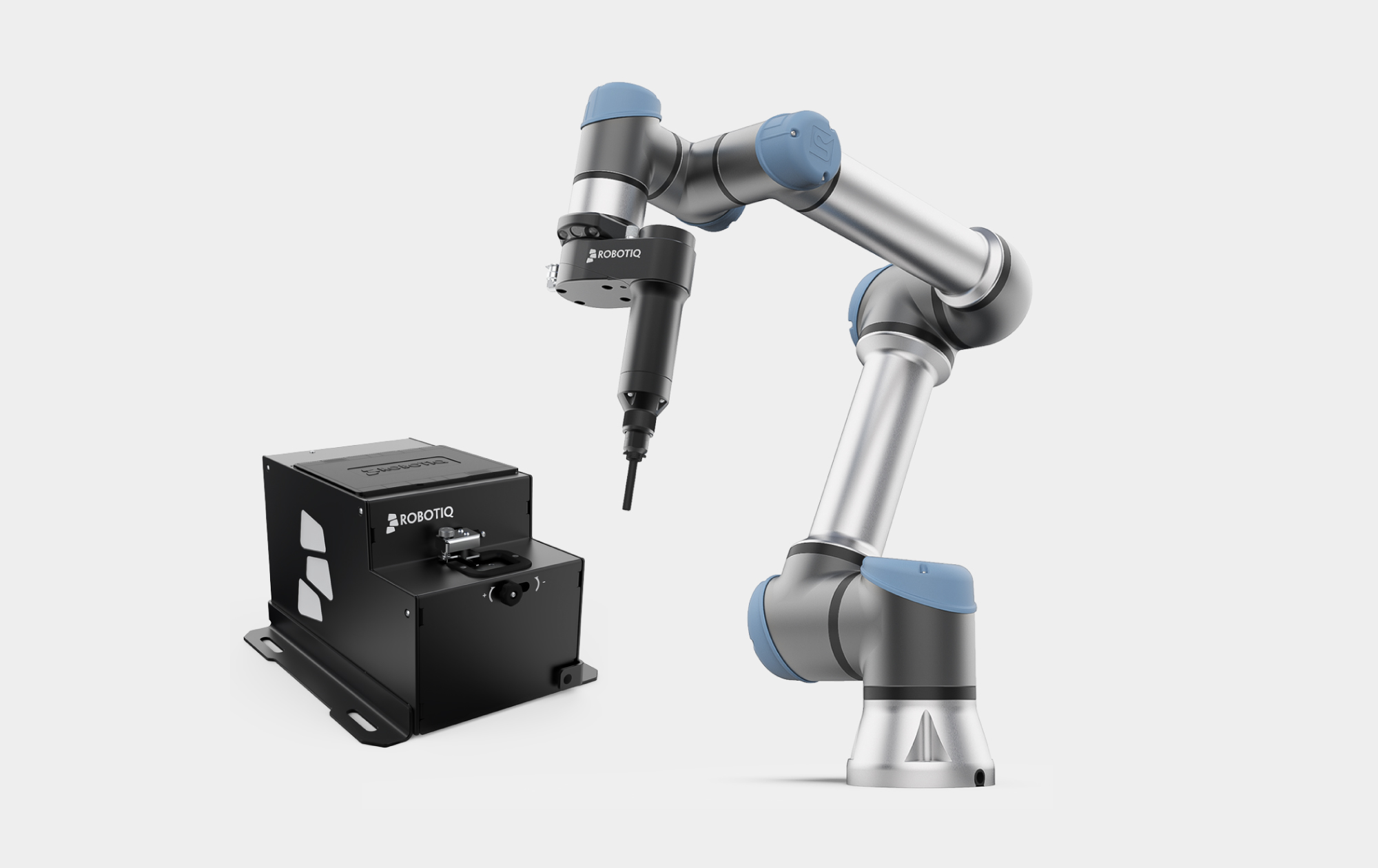

The Robotiq screw tightening solution enables

Improve productivity.

Assembly is done by humans, and screw tightening is done by robots.It enables the construction of a new production system for cooperation and collaborative work between humans and robots.

IDEC Factory Solutions adds safety measures suitable for the customer's work environment, allowing the system to be used safely and securely.

Main features

Respond to production changes in just 5 minutes

Robotiq's screw tightening solutions are designed for high-mix low-volume production. You can reconfigure within 5 minutes.

Tightening screws around the clock

Reliable and efficient screw tightening solutions eliminate the risk of product recalls and assembly line downtime.

intuitive to use

Robotiq Screwdriving URCap integrates force sensing and force control for easy and automated programming of screw pick-up and tightening tasks.

Frees workers from the risk of injury

Automating the screw tightening process saves workers from injury and allows them to be redeployed to higher value tasks.

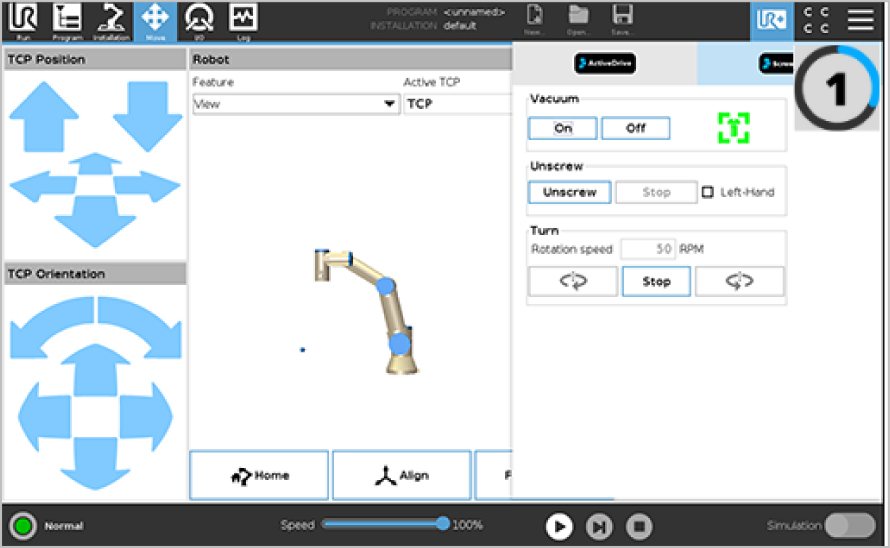

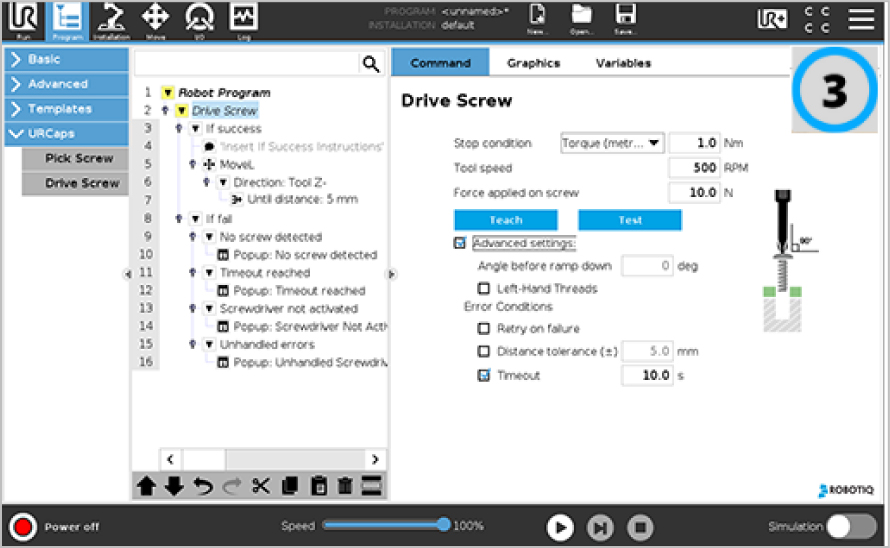

Program screen

ROBOTIQ Screwdriving URCap automates force sensing and screwdriver, screw feeder and robot interaction for easy programming.

-

- 1

Operation check

From the teaching pendant of Universal Robots,

Direct screwdriver body and parts feeder

You can control the sensor. -

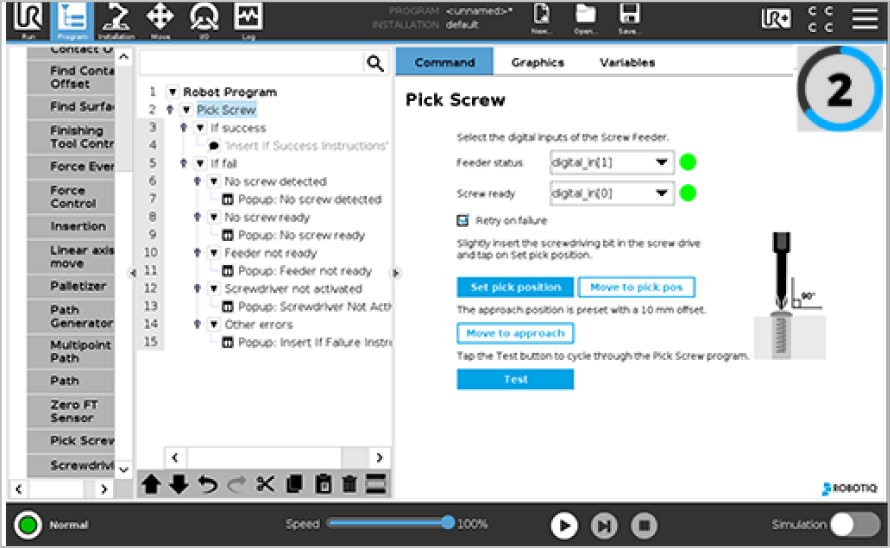

- 2

Setting the screw pick-up command

Check the status of the parts feeder and set the sensor, etc.Also adjust the position to pick up the screw.

-

- 3

Setting the screw tightening command

Using the haptic function, you can set the screw tightening position and strength.Multiple screw tightening positions can be registered.

Main components

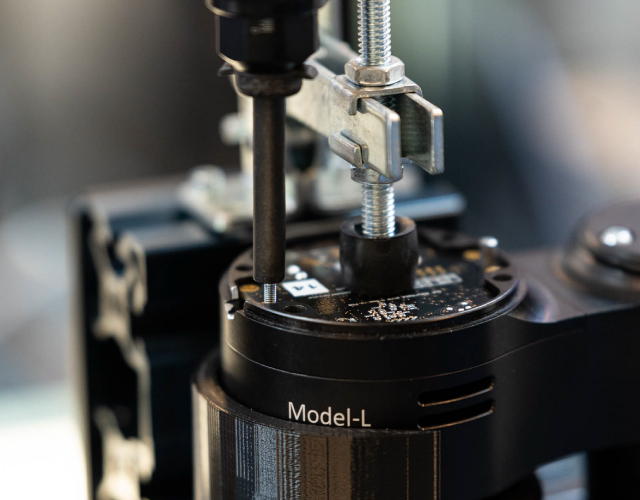

・Robotiq screwdriver SD-100

・Robotiq screw feeder SF-300

・Vacuum sleeve kit

・Screw tightening bit kit

・Robotiq Force Copilot (USB dongle)*

・Robotiq screw driving URCap (application software)

*For URCB series KIT, FT300-S is included instead.

Spec.

-

screwdriver Tightening torque 0.5/1 to 4 Nm torque accuracy ± 10% Number of rotations 1~600RPM/500RPM Compatible screw diameter M2.5 to M4 Air consumption 65L / min Body weight 1.5kg Action power 24V DC±10% Certified amount ESD safe -

Screw feeder Compatible screw diameter M2.5 to M5 Applicable screw length 6mm ~ 25mm Corresponding screw head height 5 mm Corresponding screw head diameter 10 mm Screw supply standard quantity 20 pcs/min Capacity in screw feeder 300 tsp Body weight 5.2kg Action power 24V DC

(Converted from 120/220V AC)Authentication ESD safe

Compatible screw shape

- ・Button type

・Dish type

・Hexagon socket head bolt type - ・Hexagon head type

・Plus type

・Torx type - ・Flat tip

・Pointed point

(Not compatible with hexagon socket head bolt type)

Movie

Refusal

This solution is for Universal Robots only.Not applicable to robots other than Universal Robots.Also, the Universal Robot itself is not included with this solution.

At IDEC Factory Solutions, we accept orders for a complete set including the Universal Robot itself.You can also use the Universal Robots you already have.

Please feel free to contact us for more information.