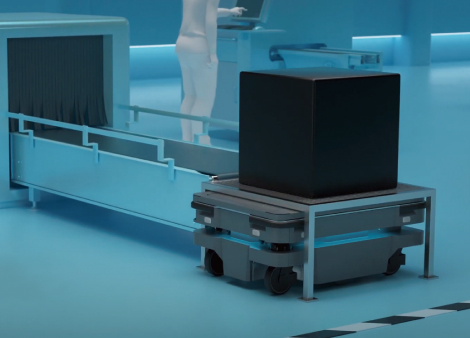

MiR equipped with a robot arm moves and transports the location,

Work flexibly on the go.

By equipping MiR with a robot arm, it is possible to move from a fixed location to different locations and perform a variety of tasks.

Overseas, AMRs like MiR equipped with a collaborative robot as the top module are called "automobile cobots" and are attracting a lot of attention as a next-generation automation method.

Application features

Introducing the features of MiR equipped with a robot arm.

- 1

It is possible to automate tasks that were previously performed by humans.

Because it has the freely movable legs of an AMR and the arms and hands of a collaborative robot, it can perform various tasks while changing locations.

- 2

High versatility

Can flexibly respond to various needs at production sites, such as FOUP transport, supplying parts to parts feeders, loading and collecting materials from processing machines (machine tending), and inspections.

MiR implementation example

Automate the material supply process with MiR equipped with a robot arm

In order to automate parts feeding into parts feeders, MiR equipped with the collaborative robot JAKA was adopted as a means to overcome the complex conditions of constantly changing material supply conditions, material pouring operations, and movement while ensuring safety.

In addition to the safe driving function that comes standard with MiR, we have added peripheral equipment such as pressure detection bumpers in accordance with the end user's internal regulations to ensure safe and secure material supply.