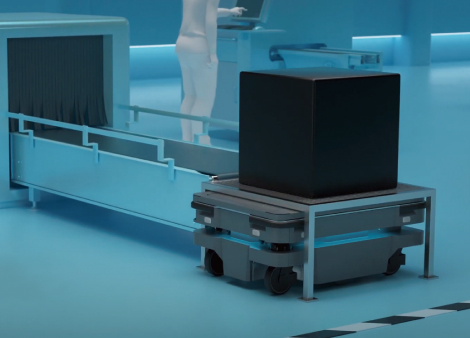

MIR equipped with a conveyor transfer top module,

Automate conveyance work that connects conveyor lines

The conveyor transfer top module is mainly used for operations that connect conveyor lines, such as loading workpieces onto the conveyor and receiving workpieces from the conveyor. It is mainly used in large-scale factories and manufacturing processes that involve high-mix, low-volume production.

Application features

Introducing the features of MiR equipped with a conveyor top module.

- 1

Flexible support for switching destinations

Autonomous driving allows you to quickly respond to changing sites that cannot be handled by conveyors or ceiling conveyors.

- 2

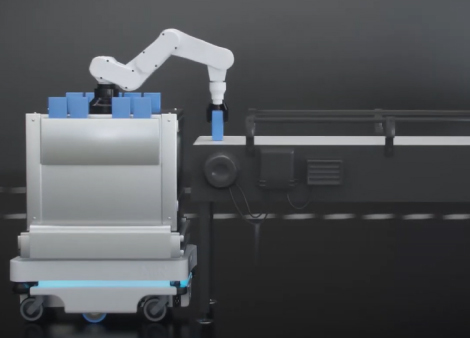

Contributes to complete automation by linking with host systems and peripheral equipment

Depending on the system configuration, transportation is also possible without human intervention.

Customer Story

Deployed as an alternative to conveyor belts on 24-hour production floors

At manufacturing sites that require high-mix, low-volume production, frequent layout changes occur.

This is an example of reducing downtime when changing the layout by adopting MiR equipped with a conveyor top module for transportation between the production line and robot cell.

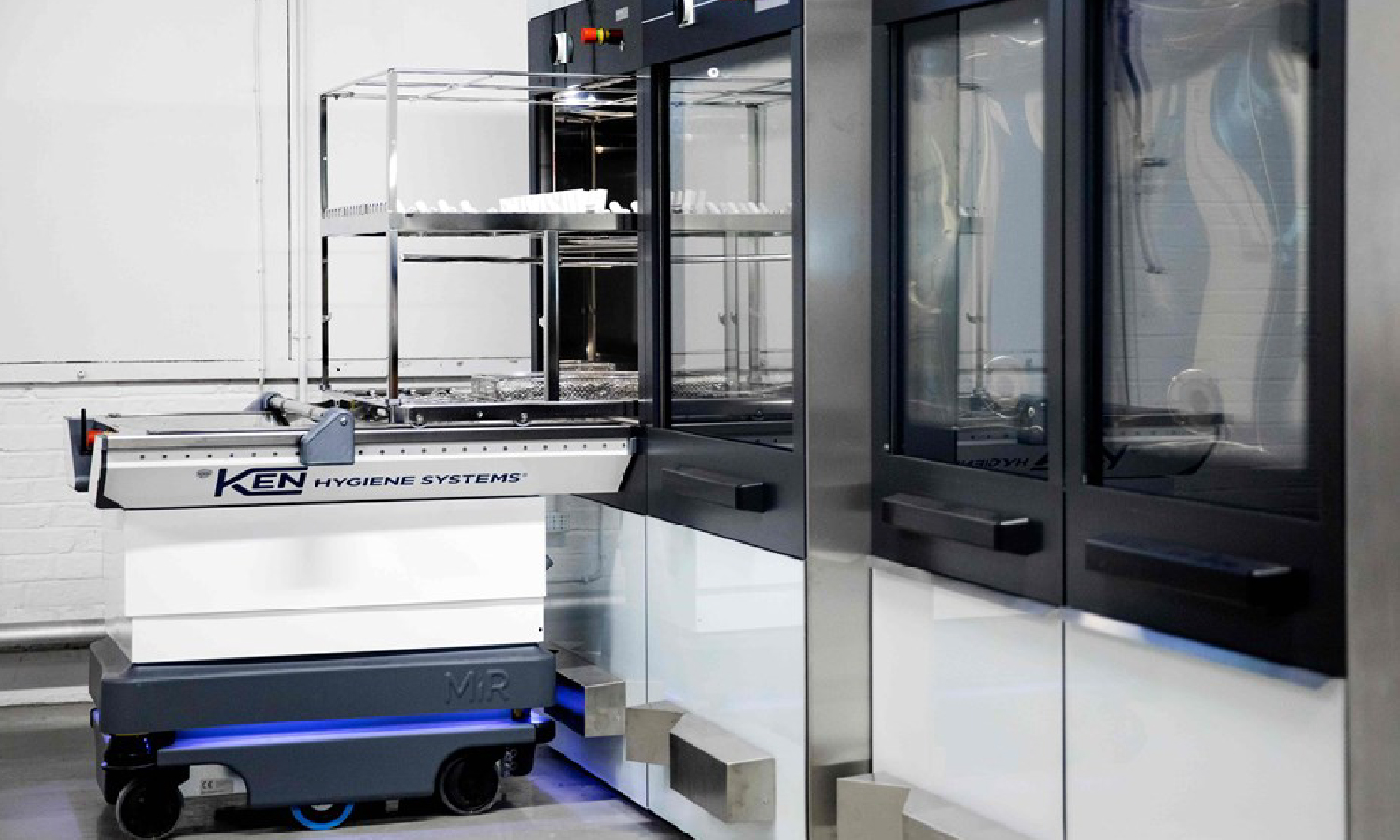

Full automation of material transport in multi-storey facilities

The MiR100, which is equipped with a roller conveyor as the top module, plays the role of a conveyor that connects production cells.

It autonomously collects and supplies materials, opens and closes doors, and controls lifts, and moves freely around the factory.

This saves significant time and reduces errors in material handling, contributing to increased productivity throughout the facility.