Safety Consulting Service"Safety Consulting" Service

If you have any problems related to system safety,

Supported by safety professionals.

What is the "safety consulting" service?

-

Our safety consulting service is characterized by practical support that utilizes our practical experience as a system integrator.As the introduction of new production methods based on collaborative work using people, machinery, and robots accelerates, there is a need for advanced systemization that not only pursues safety but also considers the balance with productivity.

Safety professionals who have acquired safety assessor qualifications support the construction of human-friendly production equipment that improves the comfort (well-being) of the working environment.

Outline of “Safety Consulting” Service

-

for compliance with international safety standards

service for

Please leave the safety of machinery and equipment that conform to overseas standards to us.

Manufacturers and operators who export machinery worldwide face complex compliance and legal issues.We help your machinery comply with a variety of regulatory requirements, such as CE marking in Europe, OSHA in the United States, or CCC in China.

We provide consulting and technical support for equipment, such as pointing out load targets on the equipment side. (Field labeling for the US market for the entire device, or arrangement and acceptance of a certification body when implementing CE marking for the European market, guidance on specific countermeasures for the machine side, consulting on safety circuit construction support, etc.)

Based on our track record of supporting many international standards projects, we offer a wide range of consulting on the electrical and hardware aspects of the entire device equipped with a control panel, in addition to design changes to comply with international standards.

Use scene

- We export equipment to North America and the EU,

i don't know where to start- Not sure if the risk assessment is done correctly

- Lack of confidence in performance level calculations

- I don't know how to create a technical document (TCF) properly

- I know that "regulations" and "standards" have been revised,

I don't know what the impact is

-

for Safer Collaborative Robot Systems

Services

Leave the safety of your collaborative robot system to us.

In collaboration between humans and robots, robots and humans share a workspace and work simultaneously.No two human-robot collaborations are the same.Even if the robot used is developed specifically for human collaboration, the risk assessment of the application must be carried out individually.

Common standards such as IEC 61508, IEC 62061 and ISO 13849-1/-2 form the normative basis for functional safety in applications.In addition, the standard ISO 10218-1/-2 for safety of industrial robots and especially the standard ISO/TS 15066 for robots in collaborative mode should be considered.

Many people may be thinking, "I want to have a third party participate in the risk assessment to improve safety as much as possible."

As a collaborative robot system integrator, we have extensive experience in building collaborative robot systems.We respond to requests to improve the safety of production sites where humans and robots work together as much as possible and to eliminate risks.

Use scene

- Not sure if the risk assessment is done correctly

- Lack of confidence in performance level calculations

- Lack of confidence in safety measures

- I removed the safety fence, but is it really okay?

- I don't know how to measure the collision force of the collaborative robot system

- In order to introduce collaborative robots, it is necessary to review internal safety rules.

Likely, but don't know where to start

-

Automatic guided vehicle system (AGV system)

Services for safety

The safety of automated guided vehicle systems (AGV systems)

Please leave it to us.The ISO 3691-4 standard (JIS D 6802) clearly defines requirements for the safety of automatic guided vehicle systems.This standard is currently considered the most important international standard for automated guided vehicle systems.

If you are using an AGV system in a production or distribution facility, ensure that the system is not only safe to design, but also safe to use and productive, taking into account all space and infrastructure conditions. required to be available.

Avoiding jams, obstacles and accidents improves safety, optimizes transportation operations, and increases transparency, efficiency and productivity.

As a system integrator, we have worked on many constructions of unmanned transport systems.We support the construction of optimal unmanned transport systems through consultations based on our experience as a system integrator.

Use scene

- Necessary safety measures for introducing AMR, what to start with

do not know- There are various types of transport robots,

Are all the same safety measures okay?- I don't know how to do a risk assessment for the AMR system

- In order to introduce AMR, it is necessary to review the company's safety rules.

Likely, but where to start?- Lack of confidence in safety measures

We will propose and implement the most suitable service according to your needs.

Seminar

We plan and implement seminars based on the level of engineers, keeping in mind compliance with standards.We also support correspondence with certification bodies as part of new employee training and in-house training.

technical meeting

When working on the system concept and detailed design, we will respond to meetings in a Q&A format regarding points to meet international standards, domestic laws and end-user safety requirements.You can freely set the theme according to your wishes.

Support for formulating safety standards for in-house equipment

We will measure and evaluate the impact force and pressure of the robot required when introducing the collaborative robot according to the standard.It also supports quantitative evaluation of pain and damage on the human body that occurs during contact.

pre-check

Check compatible models and similar models in advance and research the applicable standards.Confirm the structure and report the result.We will also explain the necessary documents based on our research.

Confirmation support for CE mark conformity

We assist you in confirming compliance with the CE marking directive, which is required when exporting electrical and electronic equipment to the EU region.

SISTEMA utilization support

We support how to use SISTEMA (safety-related control system evaluation software) and data creation in a seminar format.

Risk assessment support

Based on ISO 12100, we support the preparation of a list summarizing the implementation items of risk assessment.It is also possible to conduct seminars using actual equipment.

Collision measurement support for human-robot collaboration

We measure and evaluate the robot's impact force and pressure, which are required when introducing collaborative robots, in accordance with standards.It also supports quantitative evaluation of pain and damage on the human body that occurs during contact.

"Safety consulting" service flow

| Flow of “Safety Consulting Service” | Details | |

|---|---|---|

| STEP 1 | Inquiry | Please feel free to contact us by phone or form. First, we will arrange a date and time for the interview. |

| STEP 2 | Free interview | We will meet with you at the agreed date and time for approximately 1 hour.The first interview will be held in the form of a web conference, Depending on the content of the consultation, we will arrange a detailed interview at the site visit. During the interview, we will ask you about your situation in detail and propose how we can help your company. |

| STEP 3 | Quote | Based on your proposal, we will present a service plan estimate to solve your company's problems. If you have any questions or concerns, please do not hesitate to ask. |

| STEP 4 | official request | If you are satisfied with the contents of the estimate, we will exchange the necessary documents and formally contract. We will start work according to the contents of the contract. |

Our Strengths

- 1

Support by safety assessor qualification holders

Our company and our group have many "safety professionals" who hold safety assessor qualifications.Safety assessors carry out risk assessments based on their knowledge and skills related to machine safety and contribute to the planning of customer safety measures.

It is possible to minimize the risk of rework by providing support from the pre-design stage, from the selection of safety devices to be used in machinery to gap analysis.

- 2

Abundant track record as a system integrator

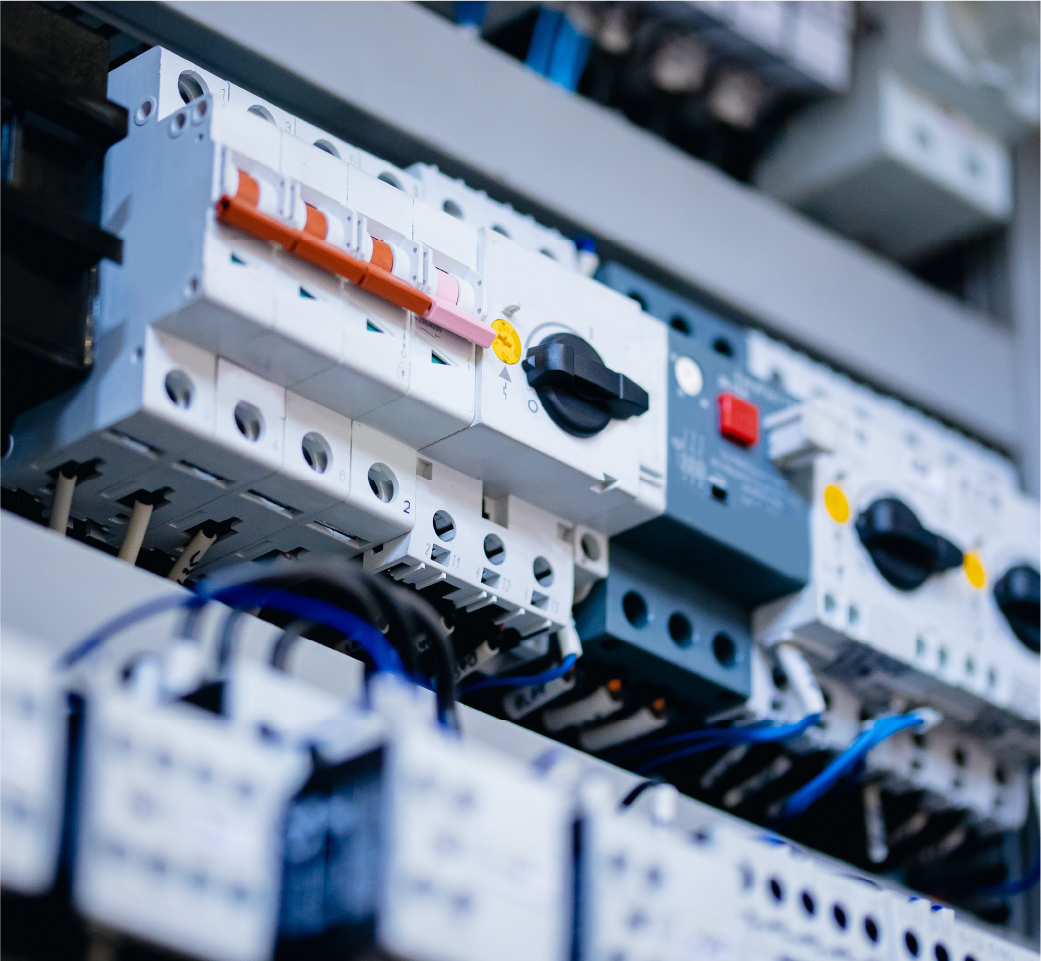

We are the system integrator of the IDEC Group.As a system integrator, we have been involved in a wide range of business fields since our founding, including "automobiles," "machine tools," and "semiconductors."

The basis for this is the control technology cultivated in FA (factory automation).

Control technology and safety are inextricably linked, and we support the safety of our customers' systems with our practical know-how cultivated at various system design and installation sites.

- 3

A close network with global manufacturers of related equipment

We are a group company of IDEC, a manufacturer of control equipment that is strong in safety, as well as a partner company of Siemens in Japan, Rittal, and Harting, which are also strong in the overseas global market as an equipment manufacturer.

From this close network, we can procure the equipment required to construct the safety circuit of the system by making the most of each company's strengths.

-

Contact UsSafety consulting service

For details, please contact us individually.