Robot SystemRobot System

Going beyond automation

Looking ahead to the arrival of a new society in which humans and robots collaborate

-

In the FA (Factory Automation) business, we have supported the automation of many production sites. However, while automation is moving forward for various processes, the reality is that there is still a lot of work that relies on human hands. In order to promote further automation, it is essential to utilize robots in the future. With that in mind, we launched the Collaborative Safety Robot Business in 2015.

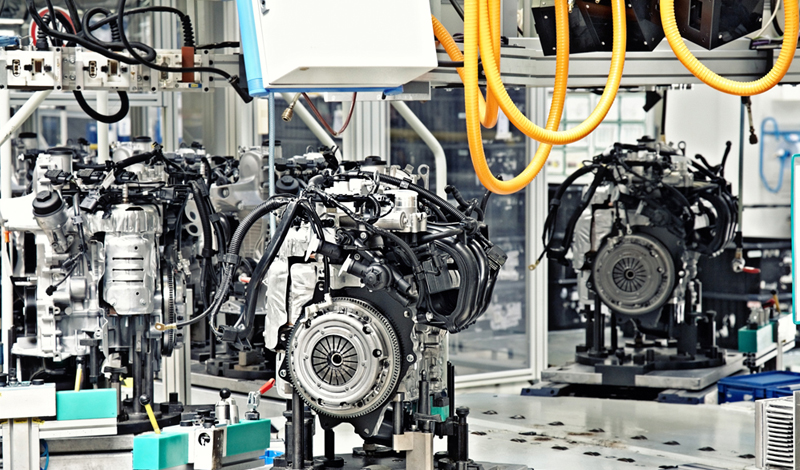

The highlight of this business is that it specializes in collaborative robots. Industrial robots, which were mainstream before the spread of collaborative robots, have been fixedly used in situations where relatively large production lines, such as those for automobiles and machine manufacturing, are surrounded by fences and separated from human work to ensure safety. Therefore, although this is suitable for repetitive simple work, it is not suitable for manufacturing sites that need to flexibly respond to changes and variables that depend on the situation.

However, along with technological innovations, robots have been made smaller, and due to the relaxation of laws and regulations, it has become possible for humans and robots to collaborate without fences between them. New robots have been produced one after another in the industrial robot genre that are made for this working together with humans, and these are collaborative robots.

Recently, we have added autonomous vehicle transport robots (AMR / AGV) to our new product lineup to meet the growing need for them in the logistics industry.

Standing at the frontier of collaborative robot system construction

-

With the progress of the times, manufacturing sites have changed significantly from an environment where humans and machines are separate to a new stage where humans and robots collaborate.

Behind this are issues such as labor shortages due to the decline in the working-age population of Japanese society and further improvements in productivity due to the intensifying competitive environment. Now, collaborative robots are attracting new attention from the viewpoint of preventing the spread of COVID-XNUMX.

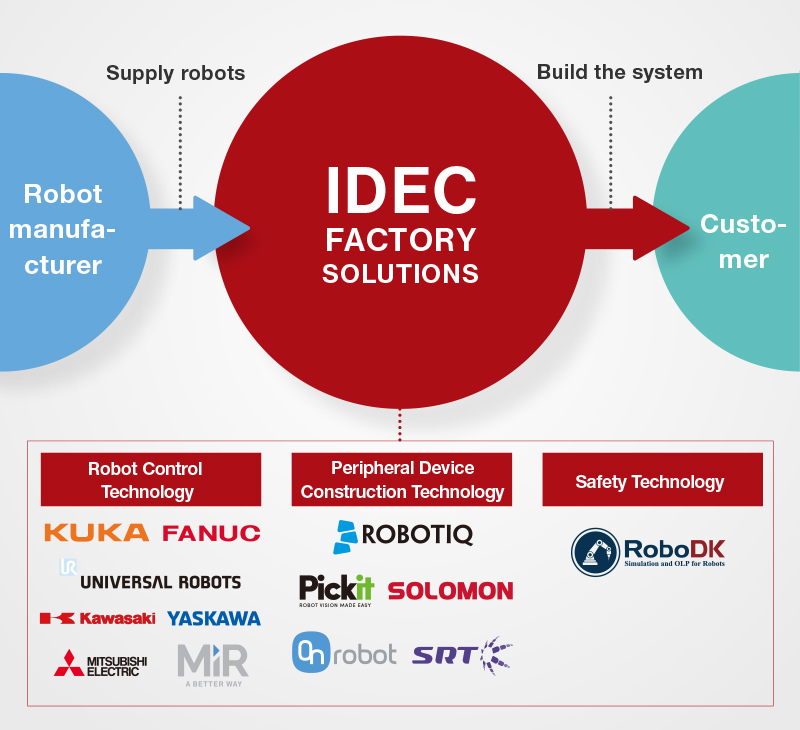

While we act as a robot SIer (system integrator) that builds robot systems as our customers’ partner, we also play the role of a sales agent for various collaborative robots and peripheral equipment manufacturers in Japan and overseas. This plays an important role in popularizing collaborative robots.

We established a collaborative safety robot technical center in Ichinomiya City, Aichi Prefecture, as a new base for collaborative robots. We provide total support from selecting collaborative robots to system design, the risk assessment essential when introducing collaborative robots, and safety measures after introducing them.

Strengths as a distributor of collaborative robots and peripheral equipment

-

In order to support the construction of optimal collaborative robot systems for our customers, it is very important to have various manufacturers and channels without depending on any specific product.

This is because we can objectively evaluate the strengths and weaknesses of each manufacturer, and by closely exchanging information with manufacturers, we can build systems that make the most of the features of each product.

“What kind of problem do you want to solve?" comes before, “Which robot will you choose?”

We will not forget that introducing robots is just a means to that end.

Established the site "kyodo-robot.com" to provide a wide range of information on collaborative robots

-

When we started our Robot Systems Division, the first thing we questioned was whether there was enough information about collaborative robots out there.

Even if you search on the Internet, although there is information on manufacturers, it is difficult to find basic information such as the customer-side benefits and ways to introduce collaborative robots.

Our perspective was that our role as robot SIers was to first provide accurate information to those who need it, so we launched kyodo-robot.com.

More than three years have passed since the launch, and now we are receiving various consultations and questions every day.

System development results

Robot systems

・ Machine tending system for machine tools (lathes)

・ Machine tending system for forming presses

・ Small box ⇒ Large box Boxing system

・ Palletizing system for shipping pallets

・ Automotive parts picking system using 3D vision

・ Coating (sealing)system

・ Electronic component assembly system using a dual-arm robot

・ Soldering system using a dual-arm robotAMR transfer systems (top module)

・ AMR system with conveyor

・ AMR system with cart

・ Mobile robotic work picking system (collaborative robot + MIR)

・ Mobile robotic work supply system (collaborative robot + MIR)

・ Towing AMR system

Case StudiesSee related Case Studies

Products & ServicesView related products & services

Sharing the latest information and ways to

utilize collaborative robots

New possibilities

for robotic arms

Innovative plug and play

arm end tool

Autonomous mobile

AMR

Make the impossible possible

AccuPick 3D & AI Vision

Robot vision

made easy

Gripping, grabbing,

and holding just like human hands

Simulating robot

applications

New options in

collaborative robots