Robot SystemResponding to labor shortages

Solution for Automating Replenishment of Cardboard for Box-Making Machines Using AMR

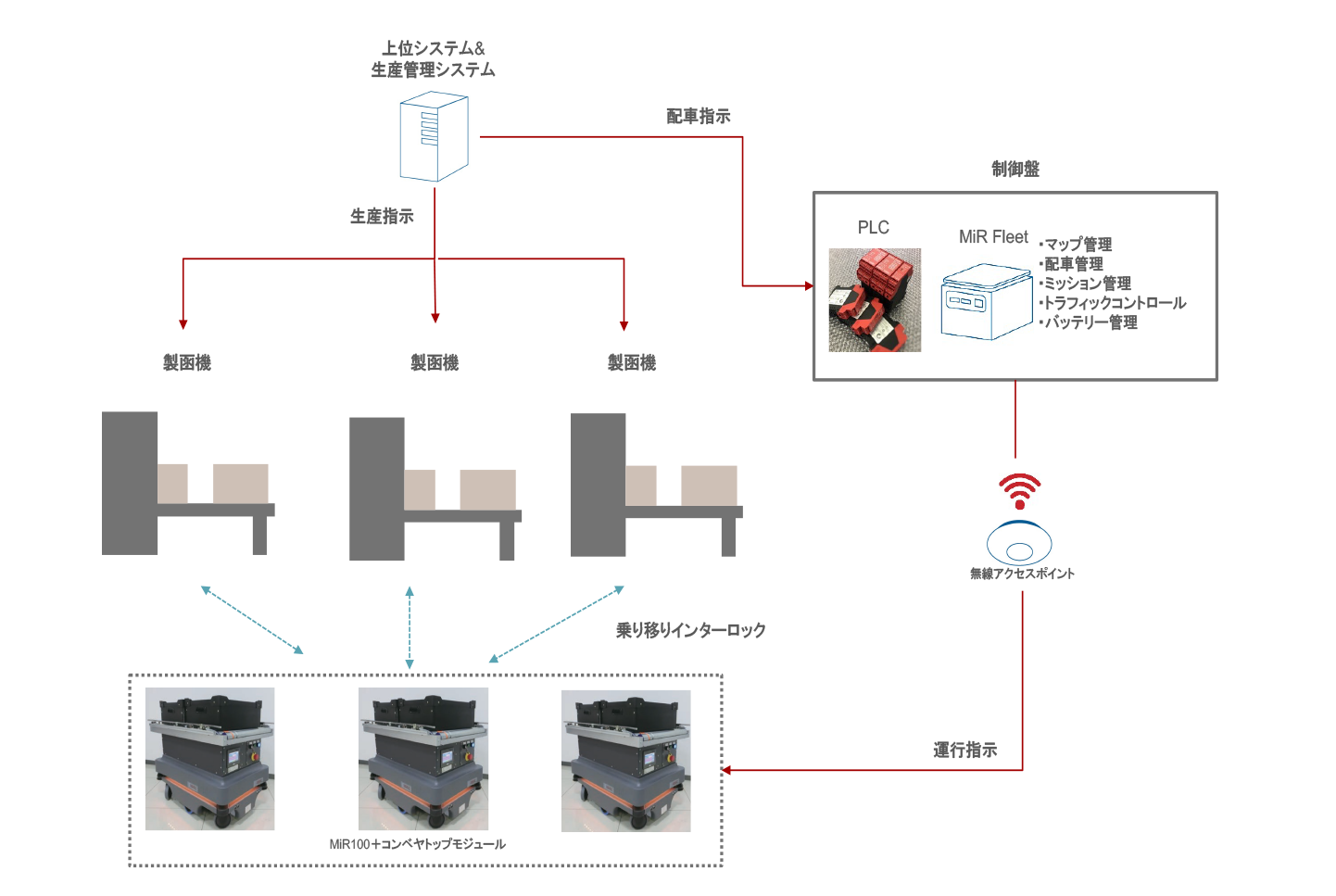

AMR was introduced to automate inter-process transfer between box-making machines and corrugated cardboard sheet storage equipment, contributing to solving a labor shortage issue.

- Industry

- Food manufacturing

- Solutions

- Resolving labor shortages

- System

- Robot System

Outline of the Case

Customer

Introduction Background

Food manufacturer Company J had set the goal of achieving as much automation as possible from the start of operation when constructing its new factory.

While each piece of equipment had already been automated, they were still looking for a way to automate the intra-factory and inter-process transport that connected their equipment.

In order to maximize efficiency, cooperation with higher-level systems and production control systems was an essential condition.

In addition, since this factory operates 24 hours a day, it was also required to construct an AGV / AMR operation program that could operate 24 hours a day along with the equipment.

Introduced Solutions

- In cooperation with equipment manufacturers, we constructed a system that replenishes corrugated cardboard for box-making machines by using a MiR100 equipped with a conveyor top module.

- It supplies corrugated cardboard sheets according to production conditions, in cooperation with higher-level systems and production control systems.

- We created operation and running cooperation systems that do not cause congestion or long-term outages and share a range of mobility with the AGV that connects other equipment.

Introduction Results

- ● Achieved automated transport between box-making machines and corrugated cardboard sheet storage equipment, contributing to solving a labor shortage issue.

Products and Services Used

MiR100

IDECFS Control Panel (Built-in MiR Fleet)

Conveyor Top Module